Makerspaces on both campuses exist to empower students, giving them hands-on experience to ideate, fabricate and iterate solutions. In Maker programs across all divisions inquiry-based learning, design and engineering come together. After an introduction with hands-on instruction on the proper use of the various tools and machines in the spaces such as circular saws, table saws, chop saws, drills, and CNC Machines like 3D printers and laser cutters, students are tasked to design solutions to various problems. These problems typically involve making life easier or more efficient, and many times are right here on campus. With the help of Director of Maker, Design, and Engineering Jim Tiffin, students design and execute plans to enhance their surroundings.

Over the summer, Claire Davis, Class of 2024, came to the School to help Mr. Tiffin organize the Upper School makerspace. Her first task was to figure out how to store parts in a way that was accessible to students and faculty. Claire came up with the “Spare Parts Center,” a wall of storage bins labeled with their names, notes, a color coding system, and a level of item quality – usability, consumability, and prototype-ability. Her design empowers Maker students to use the correct materials throughout their projects’ designing, prototyping, and final stages. Claire added, “I enjoy organizing, and being able to organize one of my favorite places on campus was awesome. I’m happy I was able to help my fellow classmates to impact the way they do every project throughout the year.”

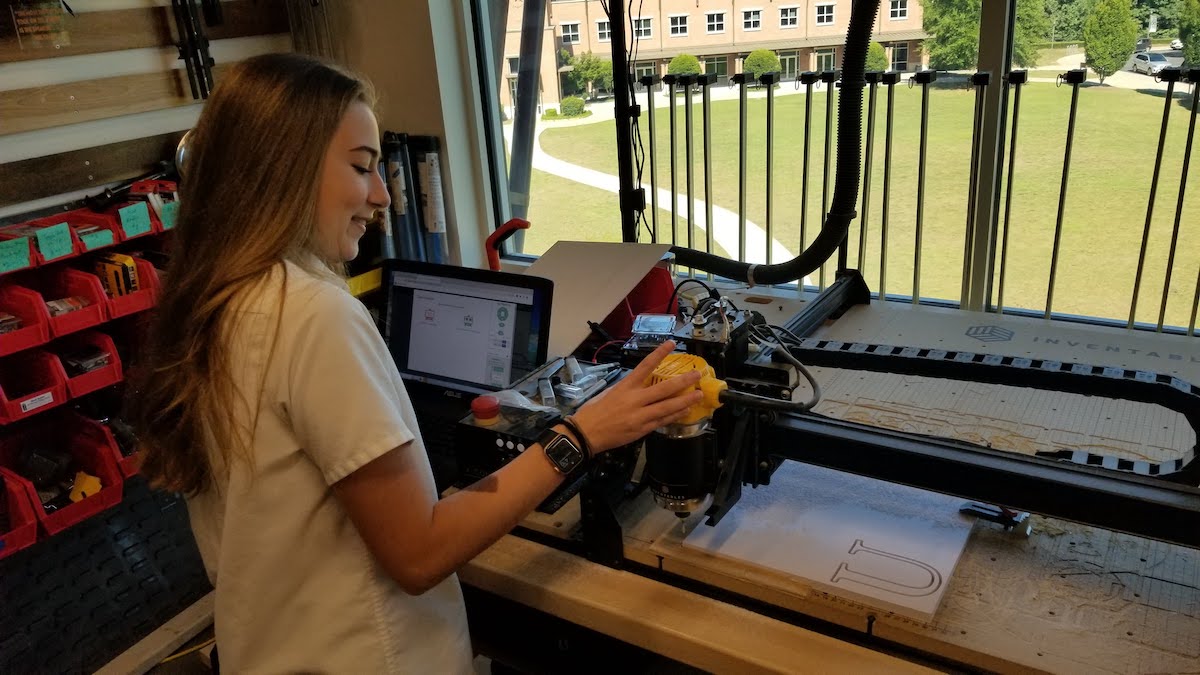

While Claire was working in the Makerspace, a gardener noticed the letter “U” on the Mount Vernon Upper School sign was missing. “Since I was already there, Mr. Tiffin suggested we try to fix the sign so I walked over to the entrance right away,” Claire said. She started by taking measurements and recording the type of material the other letters were made of. Once back in the makerspace, Claire saw that she didn’t have the correct materials but was able to design a placeholder on Easel, a design software that could control the CNC router. She cut out the letter to glue it to the sign. Once the correct materials were delivered, she expertly used the same software and machine to complete the project and replace the lost letter in time for the 2022-23 school year.

Landon Brice, Class of 2024 volunteered to repair part of the Cross Country trail for the School’s first home Cross Country meet. With just a week to complete the project, Landon jumped to action. He started by looking at what was currently in place and asking himself what worked, what didn’t work, and how he could make it better. He noticed that water had collected onto the existing solution at this part of the trail and knew he had to create a lifted walkway or water and mud would once again seep onto it. He also noticed that he would need to account for a hill in his walkway design as the trail gradually descended in this location. Landon decided the best materials to use were railroad ties and decking board for longevity. He next used a 3D design software called Fusion 360 and with this design, he used a circular saw, chop saw, power drills, and drivers to build it. With the help of a few friends, Landon hauled each piece to the construction site. While building, the group ran into a few hiccups. “The ground was not flat. We had to dig a pretty good amount. Sometimes we would screw in a two-by-four on one side and then look at the other side to see a two-inch gap so we had to find another piece of wood to plug it to screw the other side down” Landon said. His professionally designed and implemented project can be found on the Cross Country trail by the Middle School roundabout.

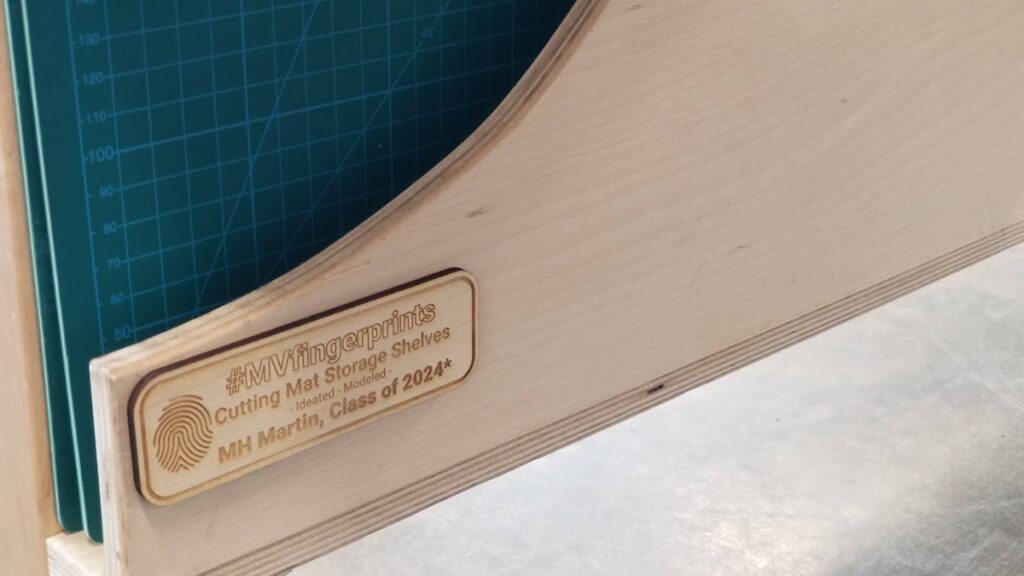

With so many student-driven projects around the School, it’s hard to tell what students had a hand in. To solve this, Maddie Coldrick, Class of 2024, and Mr. Tiffin decided to pitch an idea to Head of School, Kristy Lundstrom and Head of Upper School, Trish Bogdanchik. “Mount Vernon Fingerprints” plaques would be placed on or near any student’s handiwork around the School outlining the work that was done and the student(s) who helped. “Before I could present, I used Fusion 360 and Adobe to design cardboard iterations before using the vinyl laser cutter to configure more professional products,” Maddie said. More interactions are to come before these plaques will be placed around the school to showcase student work.

Jackson Kelly, Class of 2024 is interested in teaching his classmates about how rotary engines work. Through his passion and knowledge of cars, Jackson was able to design and 3D print an openable rotary engine model in Fusion 360 and Cura, a 3D printing software. Through this design, students are able to see how a rotary engine differs from the common piston engine from the inside out. Jackson plans to collaborate with Kristy Lundstrom and Trish Bogdanchik to find a place to display his creation so students may touch, learn, play, and explore in a hands-on environment. His goal is to share his passion for cars and encourage students to explore in the same way that he has.

One epic project many of these students were proud to participate in was last year’s Homecoming Minigolf Course. “Four classes worked on it and we all experienced lots of learning curves. Everyone learned how to woodwork, assemble, and manage teams with organization and effective communication” Landon explained. With a goal to build nine courses, each student worked diligently throughout the Mod during Maker, GTD, and after school. “I still can’t get the paint off of some of my clothes!” Claire added.

Students complete small and large projects weekly. Check out their Instagram for more Maker, Design, and Engineering stories.